A natural company

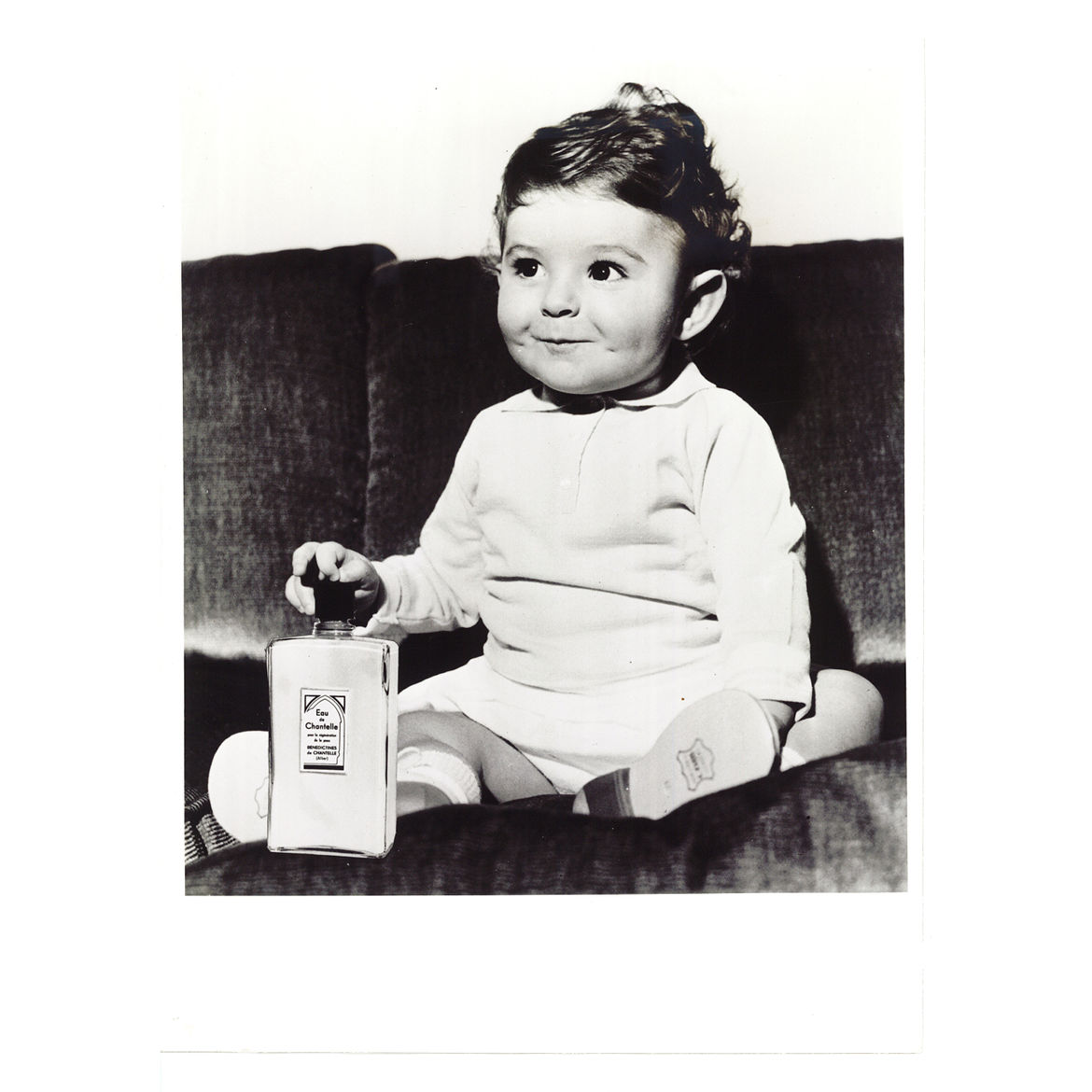

Called by the Rule of Saint Benoit to live from their work, the Sisters of Chantelle started around 1950, in the design and manufacture of products of hygiene and natural toilet. Two sisters are particularly involved: one, a chemist, will become responsible for the fabrications, and the other, a mathematician, will be entrusted with accounting. Other sisters will be trained to design, manufacture, package and package the products. The first products marketed are a toilet milk and colognes. We are in August 1954, the brand Les Bénédictines de Chantelle is launched.

Demanding on Quality

Chantelle is the only abbey in France to develop and produce cosmetics at the heart of a listed historical monument. How not to be demanding in such an environment? In order to guarantee traceability, quality and customer service, the company obtained ISO 9001 certification in 2005 and since 2010 has met the ISO 22716 standard "BPF Cosmetics". Involved in the life and development of the local economy, our laboratory today calls on the help of lay employees to offer you the best of cosmetics.

For Guaranteed Efficiency

We design your care with all the rigor of the traditions established more than 60 years ago. Over time, the reputation of Chantelle's products has grown. A laboratory was created, new products developed (creams, lotions ...), distribution was organized around privileged partners (Monasteries, pharmacies ...).

The production has been modernized in order to always meet the most demanding standards and improved formulations year after year thanks to your remarks and advice. This unique link makes us constantly evolve and allows Chantelle to be the only abbey in France to offer skincare products that are immediately noticeable. Lets try !

Conception

To develop a new product, a complete process must be followed in order to obtain the desired product.

It all starts with a brief from the listening client, supplemented by a market study and validated by the sisters. This document must take all the parameters requested by the customers but also take into account the requirements of the company (size of manufacturing tanks, sales price ...).

The person in charge of the Laboratory, Mrs. Flocon then imagines with the whole team of Research and Development the different possible formulations. At this stage they are called "paper" because they are the written transcription of what the formulators imagine. They are based on the plant knowledge held by the sisters as well as using the latest scientific advances.

Developement

This step makes it possible to validate the so-called "paper" formula and to study its possible industrial transposition. Using specific equipment, laboratory technicians perform tests that can then be manufactured in large quantities on industrial machines whose only difference in size. The first conclusive tests are put in test in the light to check their behavior in the time. In case of color variation, smell ... the development process starts again at the beginning. If a formula does not undergo any change and is validated by the sisters, it will pass the following tests that will allow to be validated by an independent laboratory approved by the Ministry of Research that the finished product will not present a risk (safety ), will suit the chosen bottle (compatibility) and will be well preserved (stability).

FOCUS ON: Natural preservatives

One of the most important themes of reflection in recent years for the sisters. Indeed, naturalists and sisters and the R & D team have worked to propose a natural preservation system, specific to each product, taking into account the interactions between ingredients. Also, we are proud to offer our customers products without parabens, without phenoxyethanol, without petrochemical mineral oils ...

These first two stages take on average 2 years and are concluded by the analysis of a dermatologist.

Manufacturing

We can call it millimetric. Indeed, in the field of skin care as in that of the drug, there is no room for approximation. To make a product there are three essential parameters, namely :

- Weight : each material is controlled and weighed (for some to 0.01 gram) before being introduced into production. The lots and weights introduced are reported on the registration form for total traceability.

- Temperature : a cream consisting of 2 phases (aqueous and fat), they must be introduced each at a precise temperature in the manufacturing tank. A gap of several degrees and emulsion will not happen, too heated, plants and integrated assets may lose their qualities...

- Agitation : here again, this brewing phase is essential and specific to each production. Very special blenders are used, taking into account the nature of the molecules to be homogenized. Too fast and we introduce air which can for example break an emulsion, too long and there will be more mass gain...

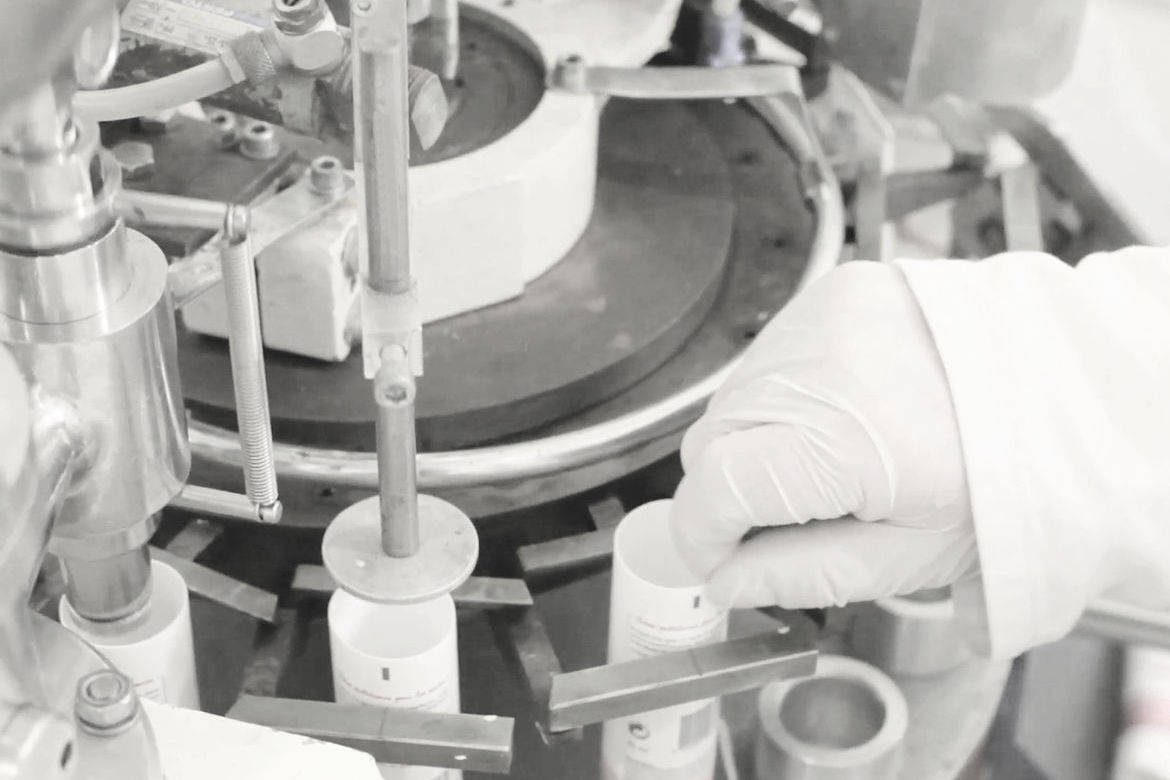

Conditionning

Manual, semi-automatic or automatic, the sisters of Chantelle have managed to evolve their production tool while remaining true craftsmen of quality. The manufacture has made it possible to obtain a "bulk" which must then be introduced into its bottle. Depending on the product, it is then necessary to affix a label, the batch of production and Date Limit of Optimal Use or Minimum Durability.

FOCUS ON : Tubes setting

For the tubes, the constraints are such that a machine investment was necessary and now allows to fill, weld, cut, apply batch and DLUO in a single gesture. This required many hours of training and led to interest in the mechanics, the setting of lasers and other electronic devices.

Expeditions

It may seem simple but we suggest you discover how your package travels in the Swiss Post network and you will certainly understand why we pay as much attention to protect the products.

Similarly, when you ask for a gift wrap or a box at Les Bénédictines de Chantelle, everything is done by hand, with a lot of common sense.

FOCUS ON: A figure that reflects quality

In total, almost 150 control points are needed between the moment we decide to launch the design of a new product and the one where you use it in your bathroom.